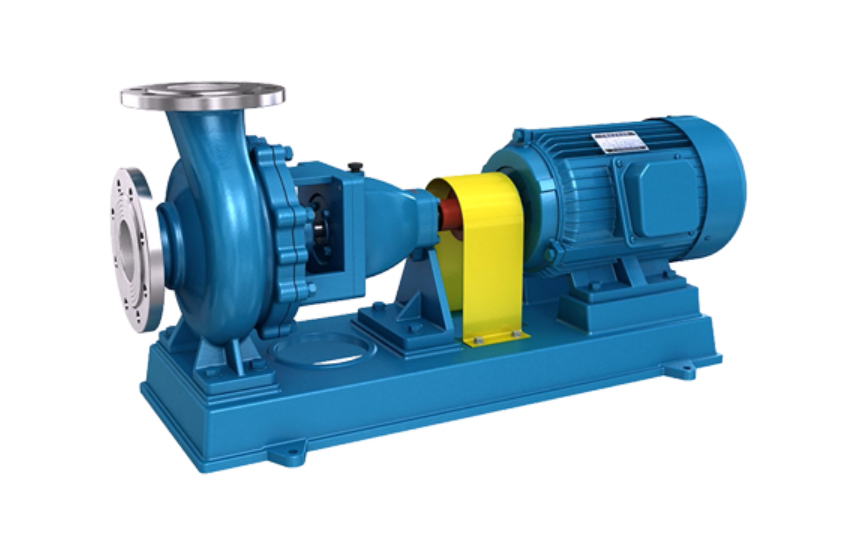

Understanding the structural characteristics of chemical pumps can improve the daily use efficiency of the equipment and make subsequent maintenance easier. Different types of chemical pumps must have structural differences, but the overall characteristics and advantages are common. Zhongcheng Pump Industry specializes in chemical industry The structural characteristics of the pump are introduced in order to help everyone have a sufficient understanding of it.

Chemical pumps are one of the key equipment used to transport chemical liquids.

The structural characteristics of chemical pumps are as follows:

1. Fine flow channel design: The flow channel design of chemical pumps is very important. Optimized fluid dynamics design is generally adopted to reduce energy loss and resistance. Special materials or coatings are usually used on the inner surface of the flow channel to improve the smoothness of liquid flow and corrosion resistance.

2. Strengthen sealing measures: Since chemical liquids are often corrosive, volatile or toxic, chemical pumps focus on improving sealing performance in structural design. Common sealing methods include mechanical seals, packing seals and magnetic seals to ensure that the liquid in the pump does not leak.

3. Selection of corrosion-resistant materials: Since chemical liquids are often corrosive, the selection of materials for chemical pumps is very important. Common corrosion-resistant materials include stainless steel, engineering plastics, rubber, etc. According to the properties of the liquid and process requirements, appropriate materials are selected to ensure long-term stable operation of the pump.

4. Adjustable operating parameters: Chemical pumps often have adjustable operating parameters, such as flow, head, speed, etc. In this way, the pump output can be adjusted according to actual process needs to obtain the best results.

5. Compact structure and light weight: Chemical pumps often adopt precise structural design to make the overall structure compact, light in weight, and easy to install and maintain.

The above content has helped you understand the structural characteristics of chemical pumps. Simply put, in order to adapt to various complex working conditions, chemical pumps have made great efforts in flow channel design, sealing measures, material selection, etc. As long as you choose reliable quality chemicals Pumps can ensure stable transportation conditions. Considering that different models adapt to different working conditions, it is recommended to communicate with Zhongcheng Pump Industry in advance before selecting a model to match a more suitable model for the transportation project.

Leave Your Comments